SUITE (Supervising Unit for In-vitro TEsting) is a generic platform for cell, tissue and organ culture composed of two main components: a universal control unit and an array of bioreactor chambers. This system is able to perform high throughput experiments in an in vivo-like environment for a long time (more than a week). With the SUITE is possible to do multi compartmental experiments for drug testing or stimulation experiments where the influence of the environmental variables on tissue physiology is investigated.

The SUITE platform is mainly composed of cell culture chamber, a mixing chamber for pH and oxygen regulation, an heating system and peristaltic pump and an electronic circuit and electro-valve box linked to PC (Fig. 1).

Figure 1: a) The whole SUITE system: the environmental control unit and the heating box, b) Block diagram about the SUITE’s main components.

The control system is able to adjust environmental variables like pH, temperature and hydrostatic pressure, in order to simulate the physiological environment and maintain the required parameters for long time. The control box is composed of custom made electronic block that acquires signals from sensors, such as a pH-meter, thermocouple, flow sensor, pressure sensor and sends these signals to a PC through an I/O card. In particular, to keep the pH value constant, the insertion of CO2 and air in the mixing chamber was highly controlled, as showed in the block diagram (Fig.2).

The environmental control system is based and the simple GUI software interface, developed in C#, that allows an easy data collection and storing using the XML data format (Fig.3). In this way, the user can easily interact with the bioreactor system, inserting the target values and with a visual check of the controlled parameters. The user interface also serves as a tool for sensor calibration.

Figure 2: The bioreactor control user interface in the userview mode (a) and in the configuration mode (b)

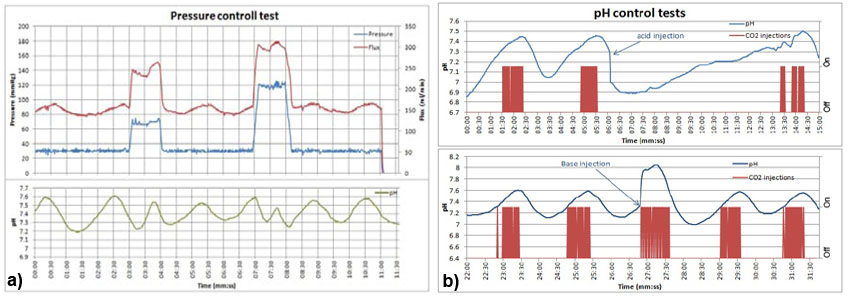

The Environmental control system was tested in order to ensure its time stability and also to verify the accuracy and resolution of the sensors and electronic acquisition units. The ability of the system to react to environmental changes was also verified. In particular, the environment stability during a pressure stimulation the system was tested using a pressure profile as target value.

Figure 3: Environmental control tests for generation of pressure profiles (a) and pH stability (b).

Contact info:

Related publications: